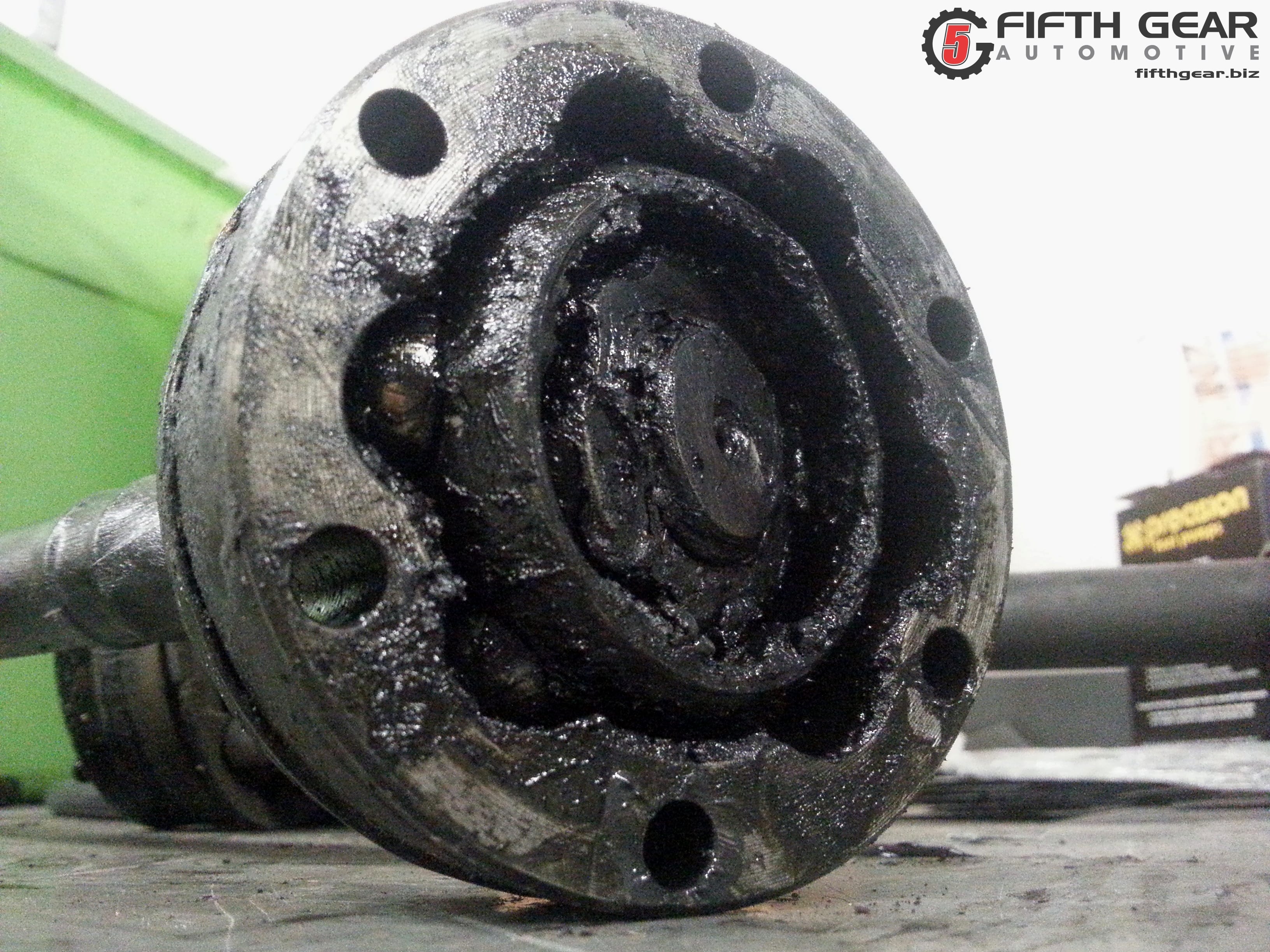

When mine pulled apart one of the bearings fell off too and the grease was so broken down that it was like thick motor oil. Not to where the gear and balls came out of the cup.

Neglected Cv Joints Why Replacing Torn Cv Boots Matters Fifth Gear Automotive Lewisville Argyle Auto Repair

If it pulled the boot off and pieces dropped out you need to clean them to.

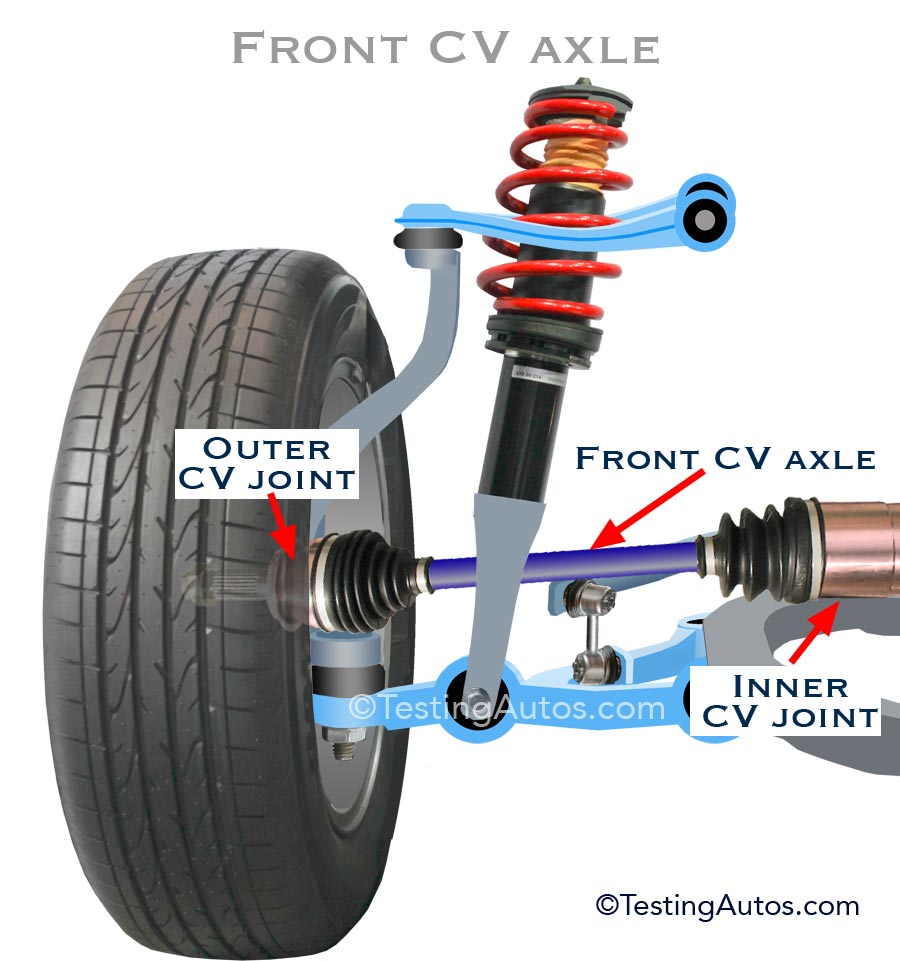

. Brake pads are moving freely in the bracket. Knock out oil seal cap inside the part of. Now lets cover more on the causes of a broken CV axle lets learn what causes this axle to break and cause you trouble.

I initially assumed that these rebuilt axles would be crap given that the core charge is higher than the price of the axle. How to Fix Stretched and Disconnected Inner CV Axle Joint - axle pull out and get out of wack. Your vehicle may be slightly or drastically different depending on the make and model.

In fact there are two main causes for this situation happening and in the next paragraphs we are going to cover both of them. One is replace the entire driveshaft which can be a pain or two clean the components put the tripod back together grease everything and stick it back in. It was like 5-6 inches away from the upper ball joint.

The process below is a general guide on the steps to replace a CV axle. Remove circlip from outer cv swing shaft down abd tap on the splined part that the circlip came off use a block of wood against the shaft and hit the wood. The cv joints can be pulled apart and put back together.

Discussion Starter 1 Oct 19 2021. You could pull the boot off and check or just warranty the whole assembly if its a concern. The first reason why the broken CV axle happens is because of normal wear and tear.

Ok so we did a motor swap put the motor back in and everything is good. This is the most timecost effective way of doing this. You have two choices.

So this past weekend I started work on my newly bought S10 1998 v6 - engine W Zr2 package sport chassis fleetside bed 4x4 its a little beat up so I knew going into it that it would need work. When installing all CV Axles DO NOT let them hang from the differentialtransaxle at any time during installation. The added stress can damage the inboard joint causing the axle to not function properly.

So all together it was 7200 us to get the new axle shipped and warrantied. The cup isnt circular like oem its more octagonal. Remove three 17mm fasteners from the bottom attached to control arm 4.

I now know from reading some reviews that GSP. After installing a circlip type axle into the transmission check to ensure the axle is properly seated in the transmission by pulling gently on the inboard housing. Anyway I pulled it all apart put the joint back together 6 ball bearings a slotted cage the knuckle with the non-parallel grooves with new grease assembled everything again tried to turn the wheel end.

Most Chrysler applications have a spring loaded inboard joint instead of the snap-ring style to lock into the transmission. But it feels like the ring clip is either gone or I dont know still turns smoothly. It almost seems like the cv joint right on the outside of the tranny is pulled apart.

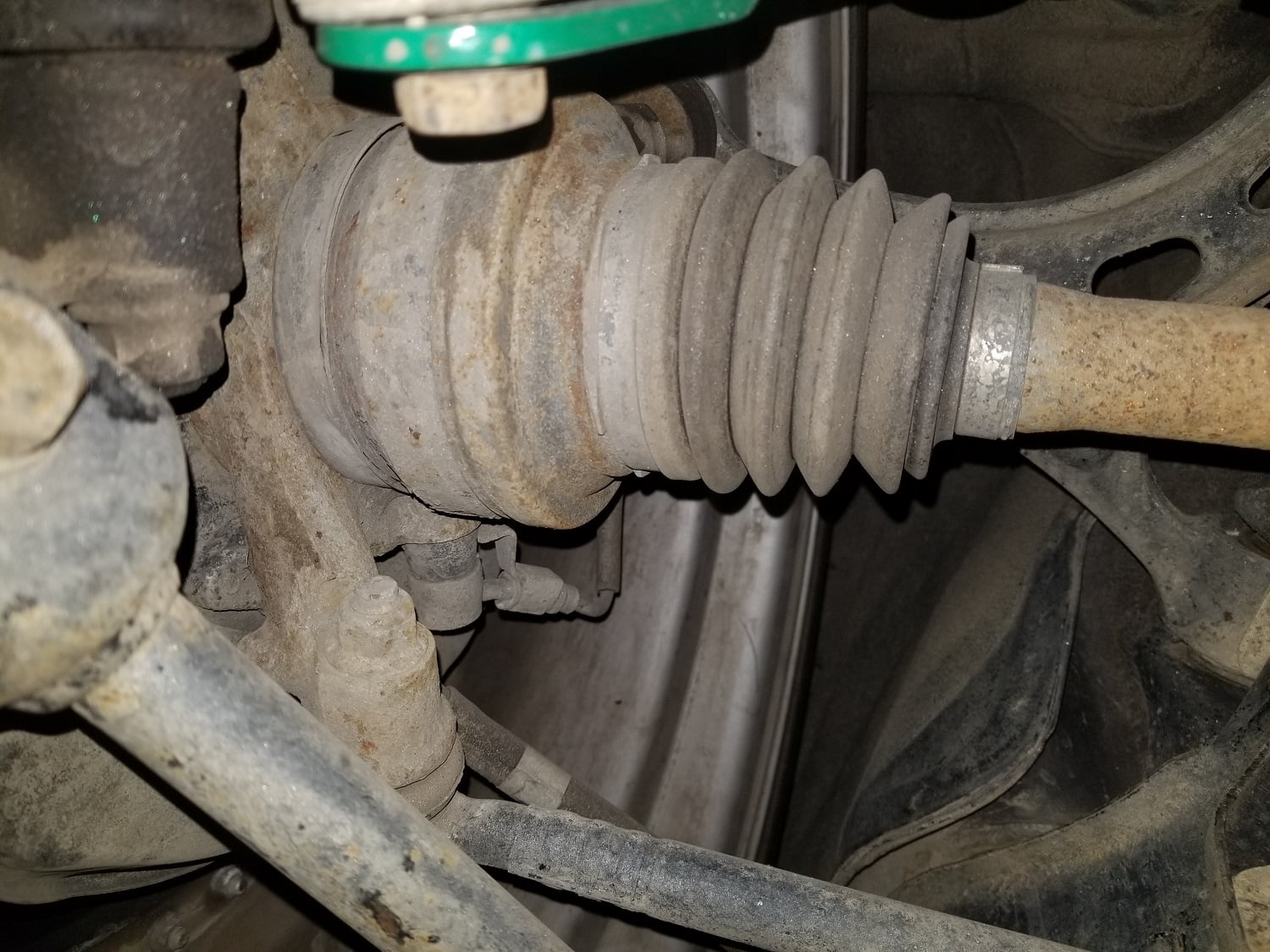

I had a GSP axle put in about 2 weeks ago 170CAD and I started having some alignment issue this past week so I brought it in for a shop to check my alignment and hopefully realign the wheels. But I just havent found that to be true. In the process of swapping out my arms the right front inner axle feels like it came apart.

I highly doubt that the car will outlast the axles. Are you sure the axle nut is torqued to spec. Was getting the axle removed and after 2.

You can use anything from a large zip tie to various clamps to secure the boot and drive on. If you were driving on it and the joint wasnt fully seated it may have been damaged. But now I cant really pull.

While putting the smaller axle in on the passenger side i think its called half shaft. Was getting the axle removed and after 2 gentil tugs to remove the axle the inner cv pulled apart. Cv axle came apart inside boot.

Enough force applied will pop it out. When installing all CV Axles DO NOT let them hang from the differentialtransaxle at any time during installation. It wont come apart unless you disassemble the suspension to allow enough room for that to happen.

Thats probably why it came apart when it was pulled on. The added stress can damage the inboard joint causing the axle to not function. Again I might just be lucky but that has been my experience.

First step to this process is to get your old boot moved up the shaft to expose the inners of the cv axle wipe out the excess grease with paper towels your going to use a bunch of them. I recently replace the front drivers CV axle since the boot was tearing apart and the inner joint bearings were binding up. Taking a closer look it was obvious Id pulled it apart when I was trying to remove the splined end of the outer CV joint from the hub.

Hanging the axle on these applications will. As you probably know your. I bought a front end kit to do my front end suspension basically everything but shock.

We could not get the hub assembly to connect to the upper ball joint. Rattle clips are in place. The most recent pair of axles I switched out were under a 96 850 that has just over 250k miles on it.

That can also cause noise.

3 Signs Of Cv Axle Trouble Salem Or Subaru Service Information

Cv Axle Teardown Whats Inside A Cv Axle Half Shaft Youtube

How To Fix Stretched And Disconnected Inner Cv Axle Joint Youtube

How To Rebuild A Cv Axle Bluedevil Products

Teraflex Mega Short Sye Kit 1310 Cv Driveshaft Package Kit Jeep Jeep Xj

0 comments

Post a Comment